testing the durability of hard plastic with a vibration chamber|Conduct the Charpy Impact Test to Ensure the : wholesalers Contact us for a demo and take the first step for assurance of the durability and reliability of your plastic products. Phone: +91 9313 140 140. Email:

[email protected]. . webGratuito. Obter. Substitui os teus cadernos de papel e reinventa as anotações em formato digital com o Goodnotes. Apresentamos o Goodnotes for Windows! Cadernos digitais. .

{plog:ftitle_list}

Resultado da Avec le globe détaillé Google Earth, inclinez la carte pour enregistrer une vue 3D parfaite ou profitez d'une expérience à 360° avec Street View. Partagez votre histoire avec le monde entier Collaborez avec d'autres utilisateurs comme dans Google Docs et partagez votre histoire sous forme de .

Using a vibration chamber for testing plastic parts offers several significant advantages. Enhanced Durability. By identifying and addressing potential weaknesses in plastic components, manufacturers can enhance the durability of their products. This leads to longer .Contact us for a demo and take the first step for assurance of the durability and reliability of your plastic products. Phone: +91 9313 140 140. Email: [email protected]. .

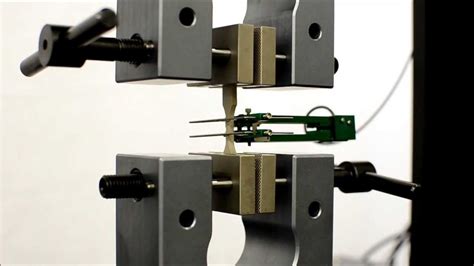

The two most basic and well known impact pendulum testers for plastic materials are the Izod and Charpy. These plastic impact test methods measure the energy absorbed by the specimen caused by the impact to create failure.Charpy and Izod impact testing are common methods of identifying the ruggedness and strength of a material. The total energy of the material is absorbed. A direct relation exists between the .The test measures the notch sensitivity and impact toughness of engineered materials such as composites, polymers, metals, and ceramics. The dimensions of a typical Charpy impact test .One of the most reliable and frequently used methods for testing the hardness of rigid plastics is by employing the Shore hardness scale. Shore scale A is perfect for measuring the hardness .

Vibration Chamber for Testing Plastic Parts?

Testing of Plastics and Rubber

Fig. 1: ZwickRoell testing equipment for materials and components. The range of application includes creep tests, quasi-static testing, dynamic methods, high-speed tensile tests, impact .

Understanding plastic material compatibility and joint design is critical to achieving optimal weld strength and meeting industry standards. Discover how to optimize joint configurations and manage material properties .The impact test apparatus determines the impact resistance of hard plastic by two different testing measures i.e. Charpy impact test & Izod impact test.

Testing Tensile Strength of Plastics: ASTM D638 Standard

When it comes to assessing the impact resistance of hard plastics, two prominent testing methods stand out: the IZOD and Charpy impact tests. Both methods are widely used .Battery Temperature, Humidity, and Vibration Test Chamber is a versatile testing solution designed for reliability, identification, and environmental stress screening across electronics, automotive, and telecommunications industries.Wider Range: Chambers can simulate a broader range of temperature and humidity levels, suitable for testing products in diverse environments. Accelerated Testing: Chambers speed up testing by exposing products to . The development of CECs is a testament to technological advancement. Innovations such as Programmable Temperature & Humidity Chambers and Environmental Stress Screening Chambers reflect the .

Measuring Toughness Of Plastics Using Izod/Charpy Impact Tester

In the realm of quality inspection and testing, the highly accelerated stress test (HAST) stands as a vital method for evaluating the reliability and performance of various products in the face of extreme conditions.Fons Solutions is founded in 2014 and located in California, USA. We develop and produce Reliability and Durability Testing and Climatic & Environmental Simulation equipment, including Humidity Chambers, Temperature Chambers, Vibration Test Systems, Drop testers and many others. We are committed to provide the best solutions to Environmental Test.Environmental test rooms and laboratory-scale environmental test chambers are commonly available. Interface. Selecting environmental test chambers and rooms requires an analysis of user interface options. Chambers with front panels include inputs such as keypads, dials, and switches for adjusting ranges and controlling parameters. Benchtop Temp Humidity Test Chamber | -40℃ +150℃, -70℃ +150℃ → Benchtop temperature humidity test chamber support customer reliability testing with small size and amazing testing performance. When the temperature and humidity rising, when the benchtop environmental chamber working with a mistake, In order to prevent the test sample from .

Discover the best vibration damping material such as viscoelastic polymers, elastomers, engineered plastics, and metal alloys to effectively reduce vibrations. Injection molding, compression molding, CNC machining, and other processes are used to create parts with high-strength vibration-damping functions.We can also test according to your own standards or criteria. Examples of environmental and durability testing include: Carbon arc testing; Cyclic corrosion testing; Salt spray testing; Temperature/humidity – programmable chamber exposures; Thermal aging/thermal cycling; Thermal shock; Vibration (single & multi-axis; sine, random, shock)Envisys’ vibration testing chambers are made to work with either electrodynamic or mechanical vibration systems, depending on the customer's request. While each model is built to standard specifications, it can also be custom designed to meet a range of rigorous test requirements. . To maintain reliability and consistency at each stage of .

One commonly used environmental chamber in vibration environmental testing is the Thermotron SE-600-10-10. This chamber can control temperatures from -70°C to 180°C and humidity from 20% to 95% RH, ensuring that test conditions are consistent and reproducible. . The automotive industry also uses vibration testing to evaluate the durability .Vibration testing methods and equipment are evolving. They provide us with more accurate, efficient, and comprehensive testing solutions. From free vibration testing to forced vibration testing. From steady-state vibration to unsteady-state vibration. We have a variety of methods to explore the vibration behavior of objects.

Impact Tests Demonstrated from ASTM & ISO

The AGREE method of testing, an acronym for The Department of Defense Advisory Group on Reliability of Electronic Equipment, was originally designed to perform specific temperature, humidity, and vibration tests in order to improve the quality and reliability of military hardware and to conform with MIL-STD 810, 781 and 883.

what moisture level on a moisture meter for zamia

Est. 2000, Linkotest is a leading reliability testing equipment manufacturer in China. We provide overall reliability testing solutions for the test lab, including vibration test systems, shock test systems, climate test chambers, and drop test systems.Testing routinely involves employing hydraulic vibration systems with capabilities to run the test within large thermal chambers, specialized vibration-temperature testing chambers like HALT/HASS, dual thermal chambers to .

Structural vibration testing and analysis contributes to progress in many industries, including aerospace, auto-making, manufacturing, wood and paper production, power generation, defense, consumer electronics, .

what moisture level on a moisture meter for zamia plant

Vibration testing is performed for a variety of reasons: to determine if a product can withstand the rig-ors of its intended use environ-ment, to insure the final design will not fall apart during shipping, for Environmental Stress Screening to weed out production defects, or even as a form of Accelerated Stress Testing. Vibration tests are .CSZ environmental chambers can aid reliability testing by subjecting products to real-world climate and wear extremes like temperature, humidity, altitude, vibration, and more. . Vibration Test Chambers. Combining temperature and/or humidity, these chambers are designed to interface with vertical and horizontal electrodynamic or mechanical . When purchasing a new vibration testing system (shaker) or environmental test chamber, choosing the right model for your test requirements is important. . Choosing the right environmental test chamber for product testing and reliability improvement involves the following considerations: Physical characteristics of the DUT – mass, dimensions .

Automotive: Testing the durability of vehicles under combined effects of temperature, humidity, and vibrations. Aerospace: Assessing avionics, sensors, and equipment in an environment that mimics the conditions during flight. . This may include controlling temperature and humidity chambers, vibration tables, and other equipment to subject the .

Salt fog test chamber prices are typically higher than conventional test chambers. This is because salt fog chambers require additional features such as corrosion-resistant materials and specialized plumbing systems capable . An accelerated carbonation chamber is a specialized testing apparatus used to determine the durability and strength of concrete. This type of chamber is designed to simulate the natural process of carbonation that can occur in concrete when it is exposed to carbon dioxide in the atmosphere. The Benefits of Vibration Testing in Climatic Test Chambers. Vibration testing is a crucial element in climatic test chambers for evaluating the reliability and durability of products, equipment .It is equipped with a 10 Nm, 20 Nm, 30 Nm, 50 Nm or 100 Nm torsion drive for test loads from 1 kN to 10 kN. Servohydraulic torsion testing machine HCT The servohydraulic torsion testing machine (table-top model) is equipped with a 250 Nm torsion drive. It can be used for the determination of the torsional vibration for test loads up to 25 kN.

Comprehensive Environmental Vibration Test Chamber; Transport Vibration Testing Machine; . Excellent Customer Service for Environmental Test Chambers Lets Chat Lets Chat Environmental Chambers High-Quality Products, Cost . It will present case studies that highlight the identification of failure modes, reliability improvements, and .Chamber testing parameters can be selected for qualification testing where product failures are usually cause for rejection or chamber parameters can be selected for reliability testing. During reliability testing, products are stressed beyond use temperature to eventually precipitate failure from which product design improvement opportunities .

A phone vibration test is an online vibration simulator that helps to determine the strength and duration of a phone's vibration. This is important for mobile phone users, as it can help to ensure that their phone will be able to properly alert them to incoming calls and messages.

what moisture meter for firewood

what moisture meter is best pin or no pin

CASADA SAFADA BRASIL - MIAMI. 6k 82% 11sec - 360p. Leoskullvideo. CASADA SAFADA CAVALGANDO GOSTOSO. 2.1k 81% 5min - 1080p. Casada sando .

testing the durability of hard plastic with a vibration chamber|Conduct the Charpy Impact Test to Ensure the